Product

We offer a wide range of high quality of equipment & machines for food drying.

+8618538579801

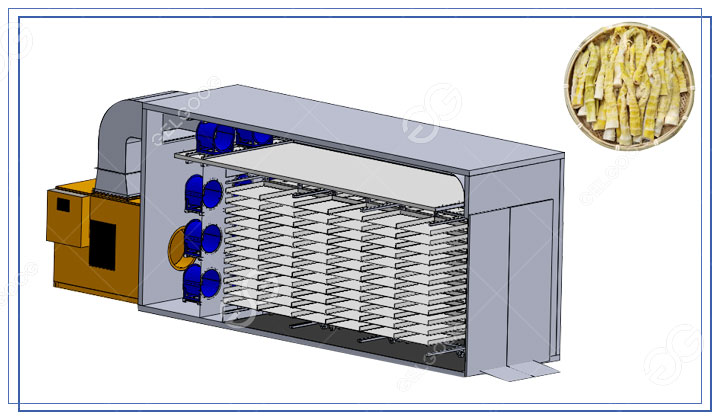

The bamboo shoot drying machine can dry and dehydrate fresh bamboo shoots to make dried bamboo shoots. Fresh bamboo shoots have high water content and are easy to deteriorate and rot. The method of drying and dehydration is used to reduce the moisture content of bamboo shoots to below the safe storage moisture content, which can effectively prolong the storage time and facilitate packaging and transportation.

Dehydration and drying is an important link in the processing of dried bamboo shoots, which affects the processing quality and drying efficiency of dried bamboo shoots. The air energy heat pump drying technology for bamboo shoots has the advantages of less energy consumption, less environmental pollution, and high drying quality, which ensures the shape, color and taste of bamboo shoots after drying to a greater extent.

1. Preheat for 90 minutes and set the temperature to 46°C;

2. Drying + dehumidification mode for 300 minutes, the temperature is set to 45°C for drying, and the humidity is set to 50%;

3. Drying + dehumidification: the temperature rises to about 55°C, the humidity is kept at 50%, and the drying is performed for 6 hours;

4. Drying + dehumidification: the temperature is adjusted to about 60°C, and the humidity is maintained at 35%, for a total of about 12 hours;

1. Good product quality: it is about 38-52*C lower than the traditional drying process, the color of dehydrated bamboo shoots is better, and the internal quality is stable;

2. High drying efficiency: the time required for dehydration of bamboo shoots does not exceed 8H, generally it can be completed from preheating to 4H after the product is produced, the drying time is short, and the single drying amount is large;

3. Long storage period, more effective than any traditional drying equipment to protect the color, aroma, taste, individual form and active ingredients of the dried products, improve the qualified rate of finished products, and reduce the defective rate of dried products;

Item | Heat Pump Dryer Parameter | |||

Model | GG-3P | GG-7P | GG-15P | Unit |

Environment temperature | -10-43 | -15-43 | -15-43 | ℃ |

Drying temperature range | 30-75 | 30-75 | 30-75 | ℃ |

Rated power | 4 | 12 | 21 | Kw |

Maximum power | 10 | 18 | 33 | Kw |

Power supply form | 380/3/50 | 380/3/50 | 380/3/50 | V/Ph/Hz |

Temperature control accuracy | ±1 | ±1 | ±1 | ℃ |

Electric heating power | 6 | 6 | 12 | Kw |

Controller | Single chip microcomputer/PLC+color screen control | |||

Noise level | ≤75 | ≤75 | ≤75 | dB(A) |

Capacity | 100-200 | 300-700 | 800-1500 | Kg |

Dehydration capacity | 9 | 21 | 43 | Kg/h(=50℃,80%) |

1. The performance is stable, the operation is convenient, and it can realize multi-function and meet the drying methods of different kinds of materials.

2. Using PLC programmable control mode, different drying curves can be set, such as: temperature, humidity and other settings, and different drying curves can be set according to materials.

3. The heat pump in the heat pump drying device not only has the function of drying, but also has the function of cooling and heating, and realizes various functions such as low-temperature processing and greenhouse heating.

4. With power-off memory function, one-key setting, realize intelligent management.