Product

We offer a wide range of high quality of equipment & machines for food drying.

+8618538579801

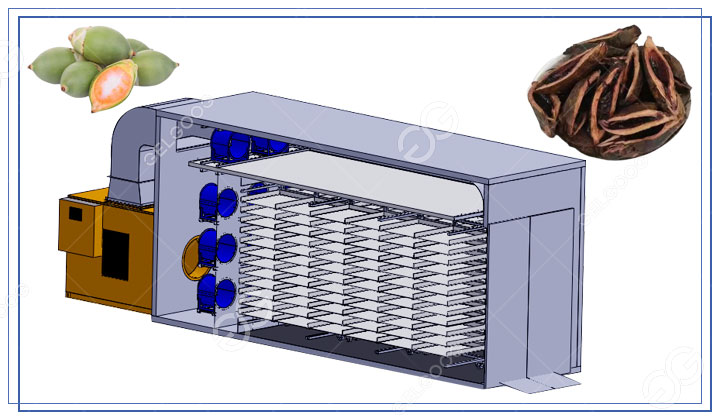

The betel nut drying machine's most hot air of the circulates in the box, it has high thermal efficiency and saves energy. Using forced ventilation, there is an adjustable air distribution board in the box, the betel nut is evenly dried, the whole betel nuts dryer has low noise and balanced operation. Temperature automatic control, easy installation and maintenance.

The first stage: When the fruit is just put into the furnace, because the water content is still high, first use the dryer to gradually heat up and maintain it for 20-24 hours, so that the water gradually evaporates, and the temperature is adjusted to automatically dehumidify. Part of the water is drained.

The second stage: shovel screening, in order to ensure the drying speed of the betel nut is uniform, the betel nut is screened, the large fruit and the small fruit are sorted, and the large fruit is placed at the bottom of the drying room.

The third stage: the temperature of the oven is gradually increased to make the water evaporate, the humidity adjustment automatically dehumidifies, and the water vapor is discharged, which lasts for 20-24 hours, so that most of the water is discharged.

The fourth stage: cool down to about 55, continue to bake for two days, so that the weight of the fruit is reduced to 25-30% of the weight of the fresh fruit.

Tips:

1. Because the areca nut is weakly acidic, an appropriate amount of alkali should be added to the clear water, which can partially neutralize the acidity of the betel nut, and can also thoroughly clean the surface of the betel nut, but it must be thoroughly washed with water before processing.

2. In order to prevent premature mildew of betel nut and cause unnecessary waste, the water of the hair should be disinfected. Try to keep the workshop as dry as possible.

3. The hair-raising process plays a very important role in the final product taste, so the hair-bearing time must be guaranteed, and the hair-bearing time is generally 5-7 days.

4. The fragrance process will ultimately determine the taste of the product, and it is necessary to strive to achieve the best combination and amount of fragrance in the use of spices

(1) Easy installation: it occupies less area and is suitable for large-scale promotion.

(2) Good drying effect: the dried betel nut has good texture, high pass rate and high purchase price.

(3) Large drying capacity: One piece of equipment dries 4 tons of betel nut at one time, which is about 1 ton higher than other similar heat pump betel nut roasting rooms.

(4) Multi-function: one machine is multi-purpose, the equipment can not only be used to dry betellang, but also can be used to dry fruits and vegetables, medicinal materials, etc.

(5) Short drying time: It only takes 4.5 days to dry betel nut at one time (the time for loading and unloading the furnace), which is 0.5~1 day shorter than the same type of equipment.

(6) Green environmental protection: zero pollution, zero emission, high efficiency and energy saving, 1 degree of electricity input plus the heat in the air can output 4 degrees of electric heat.

(7) High degree of automation: automatic temperature control and dehumidification, microcomputer integrated control system, 9 processes of drying, one-key completion, simple operation!

Item | Heat Pump Dryer Parameter | |||

Model | GG-3P | GG-7P | GG-15P | Unit |

Environment temperature | -10-43 | -15-43 | -15-43 | ℃ |

Drying temperature range | 30-75 | 30-75 | 30-75 | ℃ |

Rated power | 4 | 12 | 21 | Kw |

Maximum power | 10 | 18 | 33 | Kw |

Power supply form | 380/3/50 | 380/3/50 | 380/3/50 | V/Ph/Hz |

Temperature control accuracy | ±1 | ±1 | ±1 | ℃ |

Electric heating power | 6 | 6 | 12 | Kw |

Controller | Single chip microcomputer/PLC+color screen control | |||

Noise level | ≤75 | ≤75 | ≤75 | dB(A) |

Capacity | 100-200 | 300-700 | 800-1500 | Kg |

Dehydration capacity | 9 | 21 | 43 | Kg/h(=50℃,80%) |

High temperature and high humidity fan

Adopt high-humidity-resistant axial flow fan and circulating fan;

Hydrophilic aluminum foil heat exchanger

Adopt hydrophilic aluminum foil material, anti-corrosion, no peculiar smell;

Powerful compressor

The use of Copeland compressors has strong performance and long service life;

High precision flow control

Adopt well-known Jingkou brand Sanhua electronic expansion valve and Guotong valve;