Product

We offer a wide range of high quality of equipment & machines for food drying.

+8618538579801

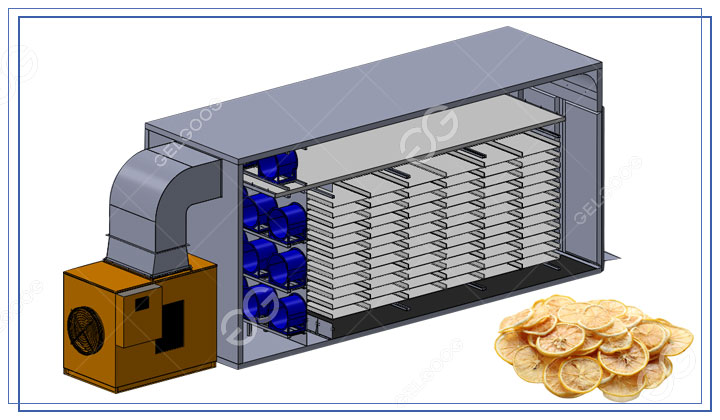

The heat pump lemon drying machine adopts a closed drying room, which can reduce the oxidation and blackening of lemon slices, accurately control the temperature and humidity in the drying room, and greatly improve the appearance and quality of dried lemons. The touch screen controls the automatic drying without care. The lemon slice dryer has the advantages of less energy consumption, less environmental pollution, high drying quality (no effect on color, nutrition, flavor and organization), and use. It is an ideal choice for many fruit lemon tea processing factories and farmers!

1. Cleaner: no combustion, no waste gas and waste water discharge, and no environmental pollution throughout the drying process.

2. Faster: drying, heating and dehumidification are operated at the same time, and the drying cost is shortened by 40% compared with the traditional method.

3. More cost-effective: make full use of the thermal conversion of air energy, greatly improve energy efficiency, 1 kWh of electricity on top of 3 kWh of electricity, and the drying cost will drop!

4. More uniform: According to the principle of air hydrodynamics, the air flow direction and flow rate in the drying room are scientifically designed, the heat distribution in each corner is even, the 360-degree drying area has no dead ends, and the product is synchronously dried inside and outside, which can be solved in one fell swoop. Solve the common problems in the drying process.

5. More intelligent: PLC intelligent control system can accurately control the temperature and humidity of the drying room, and can intelligently set different drying processes according to the preservation needs of different drying objects.

Item | Heat Pump Dryer Parameter | |||

Model | GG-3P | GG-7P | GG-15P | Unit |

Environment temperature | -10-43 | -15-43 | -15-43 | ℃ |

Drying temperature range | 30-75 | 30-75 | 30-75 | ℃ |

Rated power | 4 | 12 | 21 | Kw |

Maximum power | 10 | 18 | 33 | Kw |

Power supply form | 380/3/50 | 380/3/50 | 380/3/50 | V/Ph/Hz |

Temperature control accuracy | ±1 | ±1 | ±1 | ℃ |

Electric heating power | 6 | 6 | 12 | Kw |

Controller | Single chip microcomputer/PLC+color screen control | |||

Noise level | ≤75 | ≤75 | ≤75 | dB(A) |

Capacity | 100-200 | 300-700 | 800-1500 | Kg |

Dehydration capacity | 9 | 21 | 43 | Kg/h(=50℃,80%) |

1. American Copeland compressor, with overcurrent and phase loss protection, stable performance and long service life.

2. High-temperature and high-humidity fans, axial-flow circulating fans accelerate air heat exchange and flow, and dehumidification is stronger. The motor is all-aluminum and pure copper winding, waterproof and durable.

3. Hydrophilic aluminum foil heat exchanger, its material is anti-corrosion and mold, the heat absorption area is large, the heating efficiency is higher, and the condensed water on the leather surface hinders the air flow and produces noise.

4. Automatic flow control, flow control adopts Sanhua electronic expansion valve and four-way valve, which can realize automatic flow adjustment in cooling and heating state with high reliability and high performance.