Product

We offer a wide range of high quality of equipment & machines for food drying.

+8618538579801

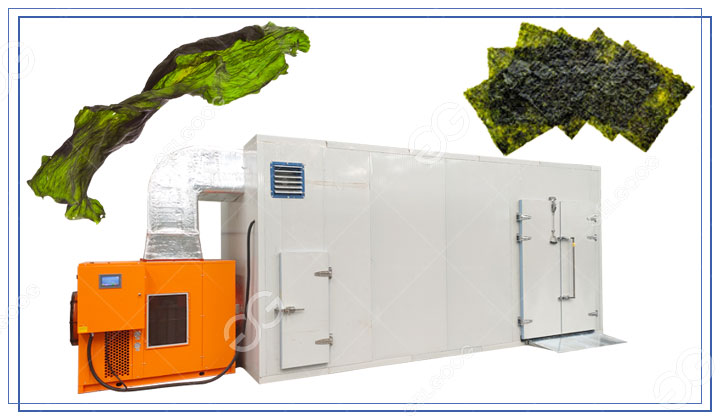

The nori drying machine is not affected by the external environment, weather, season and climate, and can work continuously for 24 hours. The drying process of the seaweed/nori is mild, and the dried seaweed has less loss of nutrients, high nutritional value, good color and good taste ! The nori / seaweed drying process is not only hygienic, but also does not pollute the environment, which solves the worries of nori / seaweed farmers in the preservation and processing, and makes nori seaweed more competitive in the market!

The nori heat pump dryer is also suitable for gim, chondrus crispus, saccharina japonica/dasima/,kombu/konbu , kelp, ladophora ect algae.After dehydrated these algaes , they will be sprinkled on rice, vegetables and fish, or used as a topping for rice balls, it is also widely used in soups, salads, omelets and other dishes and is very popular in Southeast Asia, Japan, Korea and other countries!

1. The weight of the dehydrated nori cakes must be kept within the range of 25-50 g. The water content of the nori is relatively high in the initial stage, and then gradually decreases.

2. In the nori drying process, the set temperature should be 65%-75% dried when the seaweed reaches the rear, and the drying time for combined water is relatively long.

3. After entering the upper part of the dryer, the combined water starts to evaporate from the surface and edge parts. If the front temperature is set too high, the seaweed will begin to shrink in the lower part of the dryer, and even white spots will appear, and other qualitative changes (such as redness, etc.) will easily occur.

Fine workmanship, beautiful appearance

No fuel, low energy consumption, program control, simple appearance, ordinary users who do not understand computers can easily grasp;

Run autonomously

The whole machine adopts automatic operation control, which is convenient to use, saves labor, reduces labor consumption, and saves costs for you;

Cost-effective drying evenly

The dryer adopts low temperature without killing the green, strengthens the circulating air, and strongly dehumidifies the drying, so that the natural color and luster of the raw materials are retained, the shape is full, and the nutrients are not lost;

Item | Heat Pump Dryer Parameter | |||

Model | GG-3P | GG-7P | GG-15P | Unit |

Environment temperature | -10-43 | -15-43 | -15-43 | ℃ |

Drying temperature range | 30-75 | 30-75 | 30-75 | ℃ |

Rated power | 4 | 12 | 21 | Kw |

Maximum power | 10 | 18 | 33 | Kw |

Power supply form | 380/3/50 | 380/3/50 | 380/3/50 | V/Ph/Hz |

Temperature control accuracy | ±1 | ±1 | ±1 | ℃ |

Electric heating power | 6 | 6 | 12 | Kw |

Controller | Single chip microcomputer/PLC+color screen control | |||

Noise level | ≤75 | ≤75 | ≤75 | dB(A) |

Capacity | 100-200 | 300-700 | 800-1500 | Kg |

Dehydration capacity | 9 | 21 | 43 | Kg/h(=50℃,80%) |

1. The drying temperature can be adjusted according to the thickness of the nori / seaweed.

2. Short drying time. The air-energy heat pump drying and dehydrating nori / seaweed production process requires half the time compared to traditional drying.

3. Good drying quality. The nori / seaweed produced by the air energy heat pump drying process has better color and stable internal quality.

4. Low energy. Since the air energy heat pump drying process uses air circulation, the heating temperature is determined according to the thickness of the nori / seaweed, the drying time is short, and the capacity is large. Therefore, the heat pump drying process consumes less energy and is a good energy-saving product.