Product

We offer a wide range of high quality of equipment & machines for food drying.

+8618538579801

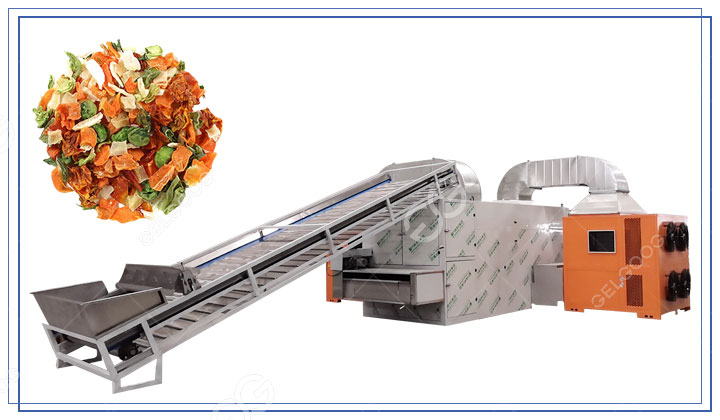

The mesh belt dryer is a continuous-flow drying equipment, used for drying flake, strip, and granular materials with good air permeability. It is especially suitable for materials with high moisture content and high temperature, such as dehydrated vegetables and Chinese herbal medicine pieces. Appropriate; this series of dryers have the advantages of fast drying speed, high evaporation strength, and products. For dewatered filter cake-like paste materials, they can be dried after being granulated or made into rods.

The material is evenly spread on the mesh belt by the feeder. The mesh belt generally adopts 12-60 mesh stainless steel wire mesh, which is driven by the transmission device to move in the dryer. The dryer is composed of several units. Each unit circulates hot air independently. Part of the exhaust gas is discharged by a dedicated exhaust fan. The exhaust gas is controlled by a regulating valve. The process of mass transfer takes away the moisture of the material. The mesh belt moves slowly, the running speed can be adjusted freely according to the temperature of the material, and the dried product continuously falls into the receiver. The upper and lower circulation units can be flexibly equipped according to user needs, and the number of units can also be selected according to needs.

Short cycle and large output

The pollution-free oven in the production process adopts a multi-layer structure, and the large drying area can realize mass continuous production. The hot air of the combustion chamber and the oven are two completely isolated parts, and all the substances formed by the combustion are discharged outdoors, which does not pollute the articles in the box and meet the export hygiene standards

Uniform heat and mass exchange, high production efficiency

The material to be processed is conveyed by a multi-layer mobile stainless steel mesh belt, and the hot air flows through the mesh belt and the material layer above it from bottom to top. The multi-layer circulation is turned over and dried layer by layer. The heat and mass exchange is uniform and sufficient, and the production efficiency is high. , The product quality is good

High energy saving efficiency, automatic circulation of pure hot air

The heat source is a high-efficiency and energy-saving hot air stove, which is fully burned indoors. The hot air after combustion is converted into suitable low-temperature heat through a heat exchanger. The converted hot air is pure hot air, which is economical and environmentally friendly.

One machine with multiple uses, saving money and space

It adopts a lifting device with a leveler, equipped with a cooling layer and a vibrating conveying device, and the discharge temperature is low, which is conducive to timely packaging; the thickness of the material layer does not need to be adjusted. The spreading area ranges from 50 square meters to 200 square meters, and a variety of models with different sizes can meet the needs of a variety of materials and different production scales.

Model | GG-1.5*6m | GG-2*8m | GG-2*9m | GG-2*10m | GG-2*12m | GG-2*15m | |

Area of dry | Four Layers | 36m² | 64m² | 72m² | 80m² | 96m² | 120m² |

Five Layers | 45m² | 80m² | 90m² | 100m² | 120m² | 150m² | |

Six Layers | 54m² | 96m² | 108m² | 120m² | 144m² | 180m² | |

Thickness of the material | 50-200mm | ||||||

Operation temperature | 40-120°C | ||||||

Drying time | 0.5-5h | ||||||

Motor power | YCT-1.1KW | YCT-1.5KW | YCT-1.5KW | YCT-2.2KW | YCT-3KW | YCT-5.5KW | |

Evaporation capacity | 300-500kg/h | 430-550kg/h | 500-600kg/h | 560-650kg/h | 620-750kg/h | 1000-1200kg/h | |

The size of input furnace | 3.2*1*2.7 | 3.9*1.26*3 | 3.9*1.26*3 | 4.7*1.5*3 | 4.7*1.5*3 | 4.7*1.5*3 | |

Fan | 80-11kw | 10C-15kw | 10C-18.5kw | 11C-22kw | 12C-30kw | 14C-55kw | |

Exhaust fan | 3.15C-1.5kw | Y5-47-4C-3kw | |||||

Output conveyor | 0.12kw | ||||||

Total power | 14.9kw | 20.7kw | 24.2kw | 28.4kw | 37.2kw | 64.7kw | |

PLC touch screen operation, simple and convenient, save labor cost

Factory direct sales, quality assurance, price concessions, reduce the price difference between the middlemen

Continuous dynamic drying, not affected by weather, material drying time is short, high efficiency

Multi-layer mesh belt structure, small footprint, large drying output, suitable for drying and dewatering a variety of materials

Drying layer by layer at low temperature and humidity, the materials are automatically turned over, and the materials are dried evenly, and the nutrients of the original materials are retained as much as possible