Solution

We provide the customize solution according to your technology and process requirements!

+8618538579801

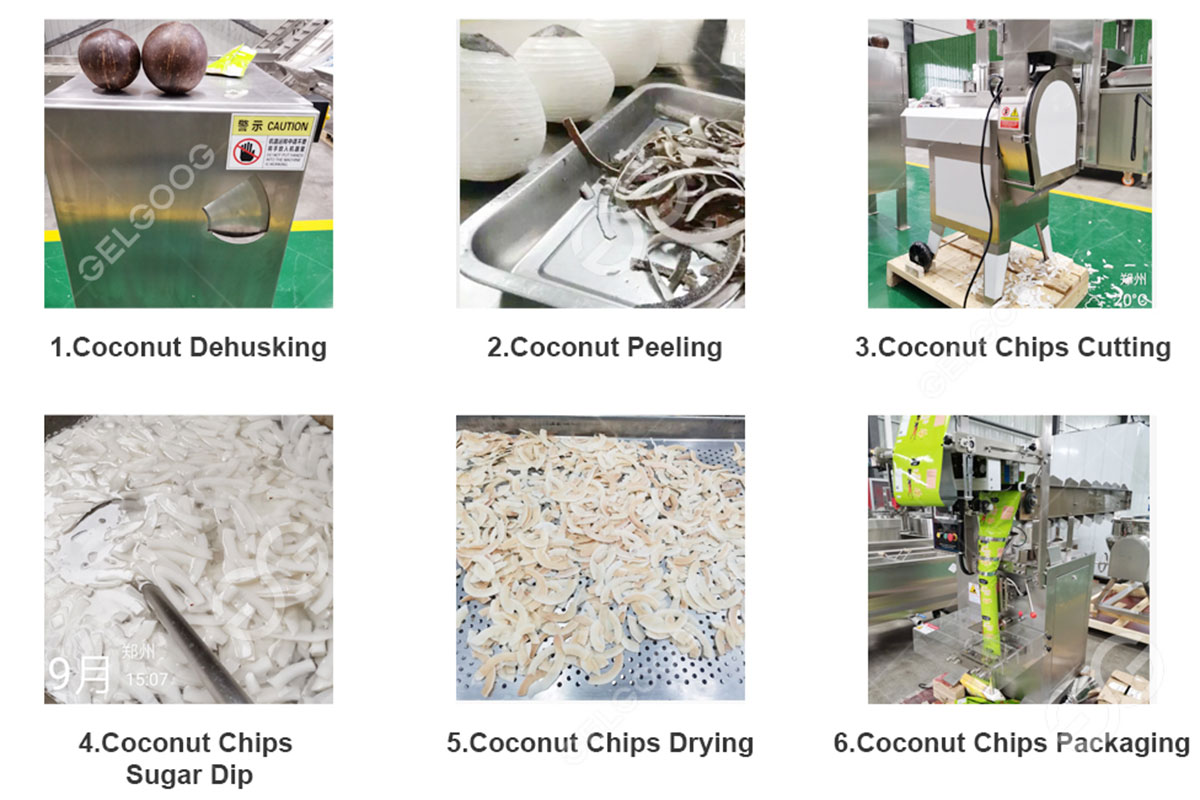

The coconut chips production line can make candied coconut chips from natural fresh coconut meat and white sugar through technical processes such as peeling, washing, cutting into slices, cooking, processing, and drying. The drying temperature is controlled at 110C-115℃, drying time: 50 minutesand then it can be gradually increased until the moisture content of the dried product is below 8%. The dried coconut flakes are evenly white and have the unique fragrance and sweetness of coconut meat.

Coconut fiber remove--Peeling--Cutting--Cooking in the sugar salt water for 20min--Rinsing--Centrifugaldehydration--Drying --Satchel packing.

The processing technology of candied coconut flakes is a bit similar to coconut horns. It is made with natural fresh coconut meat, which are peeled, washed, cut into slices, steamed, processed, and dried. Added 20% sugar+3% salt, water.

Coconut peeling machine

Coconut peeling requires two processing steps. First, a coconut husking machine is required to remove the fiber layer on the surface of the coconut. The coconut sheller is composed of cutters, scrapers, gears, sieves, etc., and has a stable structure. When using, just put the coconut on the feeding gear and rotate it to remove the shell. The operation is simple and safe.

Secondly, it is necessary to remove the gray substance of the coconut skin.

Coconut flakes cutting machine

The coconut slicing machine is easy to clean and quick to transfer. The belt adopts the highest standard food-grade PU material in Europe and the United States. The detachable belt feeding system is made of SUS304 stainless steel.

Coconut slices cooking machine

Cooking the sliced coconut with 20% sugar and 3% salt and right amount of water.Under the high temperature, the sugar and salt are fully immersed in the flesh of the coconut flakes.

Coconut rinsing machine

After above cooking, the coconut flakes surface will be very sticky. So, need to use water to rinsing.To remove excess sugar and salt on the surface of coconut flakes.

Centrifugal de-watering machine

The centrifugal de-watering adopts centrifugal methods such as inner cylinder rotation. Through the centrifugal force generated by the high-speed rotation, the excess water on the surface of the coconut flakes after rinsing is thrown out.

Coconut Chips Drying machine

Coconut chips drying machine is also called heat pump dryer. It has the characteristics of energy saving, environmental protection, pollution-free, low energy consumption, intelligent temperature and humidity control, no manual operation throughout the process, time-saving and labor-saving, and not affected by seasons and weather.

The main loss in the drying process is water, which retains the original flavor, color and nutrition of the coconut flakes to a greater extent, so that the finished coconut flakes after drying have good color and complete nutrition. It has achieved a high degree of automation, closed operation, energy saving and environmental protection, and a wide range of adaptable products. It is an ideal choice for fruit and vegetable drying equipment.

Coconut chips packing machine

Coconut chips packaging machine is suitable for packaging needs of high precision and fragile bulk materials, such as coconut flakes, potato chips, biscuits and other snacks. It can withstand greater working pressure. The automatic packaging machine has fast packaging speed and high efficiency. The process is hygienic and clean, and the operation is convenient and quick. It can complete multiple procedures at one time, such as automatic bag making, coding, labeling, weighing, packaging, and sealing.

Siemens PLC controller is simple and easy to understand, uses high-quality electronic components, and is durable;

Stable operation without interference, with three temperature control meters, temperature does not interfere with each other, and the sealing effect is more beautiful;

Intelligent human-machine exchange system, touch-screen system, easy to understand parameter setting and function switching;

It can effectively ensure the quality of the coconut flakes that are dried.

Safe and reliable, there is no danger of harm to people during the drying process of coconut flakes.

The coconut flakes drying process has low energy consumption and effectively reduces operating costs.

The temperature distribution during the drying process of coconut flakes is even, and the temperature and humidity can be automatically controlled.

Strong versatility (one machine with multiple uses), which reduces the investment cost while increasing the utilization rate and effective utilization rate of the equipment.

Using a heat pump dryer to dry coconut chips flakes not only saves time and cost, but also has a uniform and good-looking color effect. It also meets the national environmental protection requirements. The heat pump dryer hopes to bring you better economic benefits.

Coconut has high nutritional value, and has the effects of promoting body fluid, diuresis, replenishing the spleen and stomach, killing insects and eliminating chancre. Modern medical research shows that coconut meat contains protein and carbohydrates; coconut oil contains sugar, vitamin B1, vitamin B2, vitamin C, etc.; coconut milk contains more nutrients, such as sugar, glucose, sucrose, protein, and fat , Vitamin B, Vitamin C and trace elements and minerals such as calcium, phosphorus and iron. It can be seen that coconut is a good product for both medicine and food.

When the spleen and stomach is tired, appetite is weak, limbs are weak, and the body is weak, chop the coconut meat and add an appropriate amount of chicken and glutinous rice. After steaming, the diet will be more effective because chicken, glutinous rice and coconut meat are nourishing. The method of stewing soup has more beneficial effects; adding winter melon seeds to coconut can relieve lung fire; additively cold snow meat or clear tonic yellow ears can neutralize the warmth and dryness of coconut.

Share This Post,Choose Your Platform!