Solution

We provide the customize solution according to your technology and process requirements!

+8618538579801

The dried shrimp processing line uses a shrimp dehydrator instead of the traditional sun, which prevents the sun from being polluted by mosquitoes, avoids the impact of bad weather, reduces manpower and material resources, improves the quality of dried shrimp, and saves costs. For seafood For processing plants, it is a very cost-effective practical equipment that can meet people's requirements for food quality.

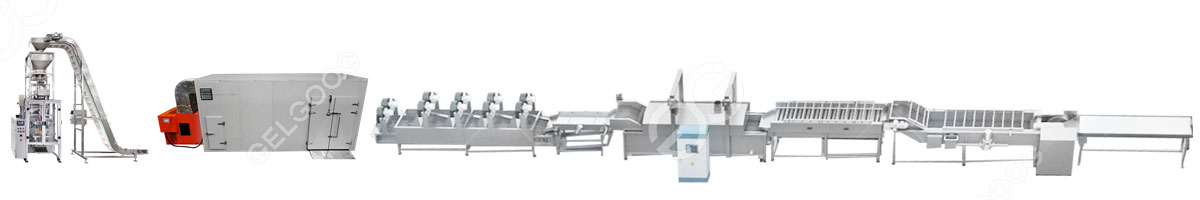

The shrimp drying process mainly includes: shrimp cleaning-blanching-air drying-grading-drying-packaging

Shrimp washing machine

The shrimp just caught from the sea contains a lot of silt, which needs to be cleaned by a bubble cleaning machine to remove the silt impurities. The shrimp cleaning machine adds the spray cleaning function during the shrimp transportation process, so that the shrimp is cleaned by the spray after the soda bath cleaning is completed. The function of this process is to replace and remove the dirty water on the surface of the shrimp to improve the cleaning of the shrimp. At the same time, the external cleaning spray water will automatically flow into the water bath after the second cleaning of the shrimp, so as to replace the cleaning water in the water bath and maintain the cleanliness of the water in the water bath, that is, improve the cleaning water. The utilization rate increases the cleaning effect.

Shrimp blanching machine

The cleaned sea prawns need to be boiled or steamed in time, sprinkled with an appropriate amount of salt, and the blanching time is just as long as the color of the prawns turns from blue and white to red. At this time, the prawns are also easier to shell. The blanching machine is an ideal blanching equipment that is often required in the color protection process of shrimp processing. The steam blanching machine integrates blanching and cooling. It is equipped with a unique superheated steam generator and does not require boiler equipment. Pressureless operation, safe and reliable.

Shrimp de-watering machine

After blanching, excess water remains on the surface of the shrimp, which needs to be air-dried to shorten the subsequent processing flow. This machine uses a low-power, low-noise fan, the blowing port is knife-shaped, and the drying air temperature is normal temperature, which effectively protects the color and quality of the shrimp itself, and the effect is better. This machine has the characteristics of wide application, high drying efficiency and convenient operation.

Shrimp grading machine

The shrimp grading machine can classify the dried shrimps according to their size. It is equipped with an automatic feeding part to realize the automatic feeding of the sorting machine. The detection speed is 300 times per minute, and the highest accuracy is ±0.1g, which can liberate labor. Work efficiency.

Shrimp dehydrating machine

1. The cooked shrimp can be dried in shell, or the shelled shrimp can be dried. After the cooked sea prawns are drained, they are evenly spread on the baking tray, loaded into the material truck, and then sent to the air-energy drying room.

2. According to different types of sea shrimp and river prawns, the temperature of the intelligent control system of the dryer should be set at a medium high temperature of 50℃~70℃, the time is about 4 hours, and the moisture content is 18%. In the drying process, a slightly larger circulating air volume is generally required, and the wind speed is also relatively high to avoid moisture staying on the surface of the dried shrimp. The control points are to inhibit the growth of bacteria and maintain the color of the dried shrimp and shrimp.

3. According to the above drying steps, the dried shrimp baked by the sea shrimp dryer has a complete body, neat appearance, natural color, pale yellow, reddish and shiny, plump meat, curved shrimp body, and unique natural fresh fragrance.

Shrimp inspection package

After the dried sea prawns are cooled to room temperature, the debris should be removed and packaged in grades, and stored in a ventilated and dry warehouse or freezer according to the factory or customer requirements.

The heat pump dryer is used in the drying room to fully dry the shrimp. The drying process has low energy consumption and effectively reduces operating costs.

The drying process is well ventilated, and the surface of the shrimp is heated evenly, without manual entry for turning. The gloss of dried shrimps is maintained, and the quality of the finished products can be unified without manual separation.

Control the corresponding parameters of dried shrimp drying, intelligently control the problems in the drying process, and intelligently handle abnormal situations.

The drying process is safe and reliable, and there is no danger of overheating or burning during the drying process.

Automatic temperature and humidity control with high accuracy. Effectively avoid the phenomenon of non-drying or over-drying caused by manual operation, reducing labor intensity and reducing operating costs.

There are various types of sea prawns, such as prawns, prawns, pippi prawns, lobsters, etc.; freshwater prawns such as green prawns, river prawns, grass prawns, ghost prawns, crayfish, etc, and brackish water prawns such as white prawns.

Shrimp is delicious, nutritious, high in protein, and rich in minerals such as calcium, phosphorus and iron, which are extremely beneficial to human health. Shrimp has finer muscle fibers, its meat is tender and soft, has a delicious taste, and is easy to digest. It is a good food for people who are weak and need to be nursed after illness.

Dried shrimp is a kind of food with very rich protein and high nutritional value. Among them, the content of vitamin A, carotene and inorganic salts is relatively high, and the fat content is not only low, but also mostly unsaturated fatty acids. Shrimp contains high-quality protein, the content in fresh shrimp is about 18%, and the content in dried shrimp is as high as about 50%. Shrimp is rich in minerals, with 146 mg of calcium, 196 mg of phosphorus, 3.0 mg of iron, and 1.44 mg of zinc per 100 grams of sea shrimp. Per 100 grams of shrimp skin, the calcium content is as high as 1760 mg, phosphorus is 1000 mg and iron is 6.7 mg. .

As a kind of seafood with rich nutritional value and low price, sea prawns are made into dried prawns, which are delicious and durable in storage, and are deeply loved by consumers.

Share This Post,Choose Your Platform!