Mali and Burkina Faso are rich in delicious mangoes, but they have not been exported as fresh fruits. Therefore, mango processing has become a reasonable choice for job creation in these West African countries. In the past ten years, hundreds of small mango drying plants have been set up to produce dried mangoes for the European market. As far as the dried mango market is concerned, compared with West Africa, South Africa is the leader in the dried mango market in Africa. South Africa has advanced mango drying technology and is equipped with relatively advanced mango dehydrating machine , so the south africa can produce higher quality dried mangoes.

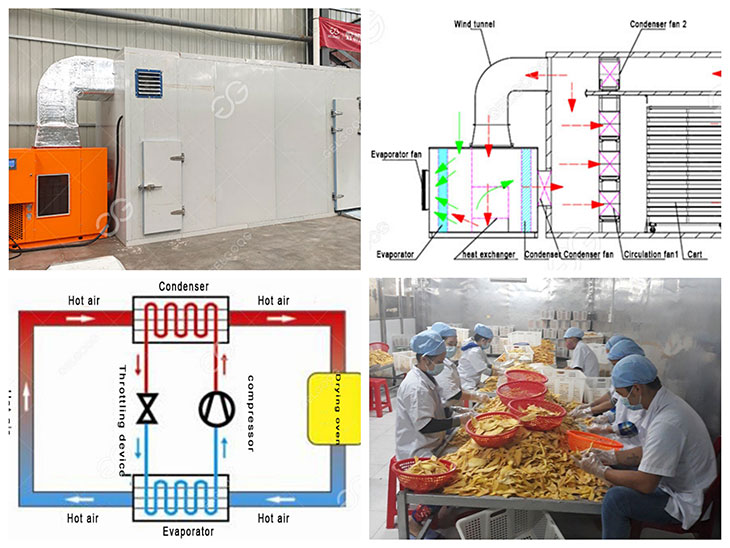

The mango drying machine south africa is an emerging drying equipment in the drying industry in recent years. Many people do not know much about it. In addition to the characteristics of environmental protection, energy saving, sanitation, etc., it also has diversified functions, extensive applications, full automation, and intelligence , mature, stable, safe and reliable.

1. The mango dehydrating machine has the functions of drying and dehumidification, and can control the temperature and humidity of mangoes. Generally, the drying time is shorter than other traditional drying methods.

2. The mango drying machine south africa is a gentle drying method, which is close to natural drying. The dry goods have good quality, good color and high grade of materials.

3. Heat preservation cycle convection drying method, staged drying program, uniform temperature in the drying room, fast drying speed, uniform heating of dried mangoes, good and stable quality.

4. During the mango drying process, the mango will not be deformed, cracked, discolored, degraded, not oxidized, dried thoroughly, rehydrated well after drying, less nutrient loss, and has a long storage period, which is more effective than any traditional drying equipment to protect the dried material. Color, aroma, taste, individual form and effective ingredients.

5. The mango drying machine south africa adopts the air jet increasing enthalpy secondary compression technology, which increases the enthalpy difference of the main circulation path, increases the air supplement channel, and reduces the exhaust temperature, thereby increasing the heating capacity of the heat pump unit and increasing the COP value. And can meet the heating requirements of low temperature environment, and save energy.

6. The mango drying process machine adopts a touch screen PLC industrial-grade control system with a man-machine interface, which can display the temperature and humidity control curve in real time, and the operation is simple.

It is worth noting that there is a shortage of mangoes in South Africa and it is looking for opportunities to expand production abroad. Therefore, if West Africa and South Africa can strengthen exchanges on dried mango production technology, experience and equipment, it will help expand their respective markets.