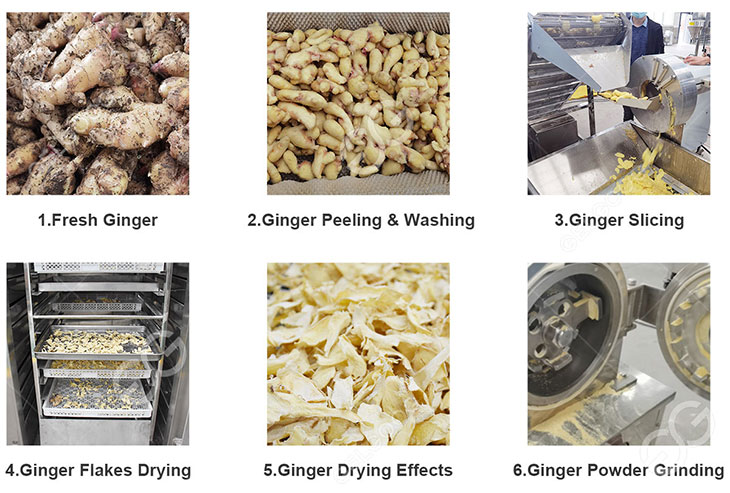

The ginger powder manufacturing process mainly include ginger washing and peeling, ginger slicing, ginger de-watering, ginger chips dehydrating, dried ginger powder grinding ect. Each ginger processing process must use the corresponding a ginger processing machine.The details functions of the ginger powder processing machine mainly as follows:

Ginger washing and peeling machine:The ginger washing and peeling machine use brush roller type washing machine, through the rotation of the brush roller, the friction between the ginger and the brush is driven to achieve the desired effect. For the hair roller cleaning machine, choose different softness and hardness of the hair brush to achieve the effect of cleaning, peeling and polishing ginger.

Ginger slicing machine:The ginger slices are shredded, and the surface of the cut products is smooth and neat. Suitable for markets, fast food distribution or ginger processing plants.

Ginger chips dehydrating machine:Ginger slice belt dryer is suitable for large-scale production of difficult-to-dry materials with low drying rate. The equipment has compact structure, small footprint, simple operation, convenient maintenance and stable operation.

Dried ginger chips powder grinding machine:After the sliced ginger was dehydrated in the mesh belt dryer, then we need to grinding the dried ginger chips into ginger powder.The fineness of ginger powder is adjustable from 20 to 120 mesh, which can be achieved by changing different screens.

Here is the ginger powder manufacturing process, if you also interestedi n the ginger powder business ,welcome to contact us freely!!